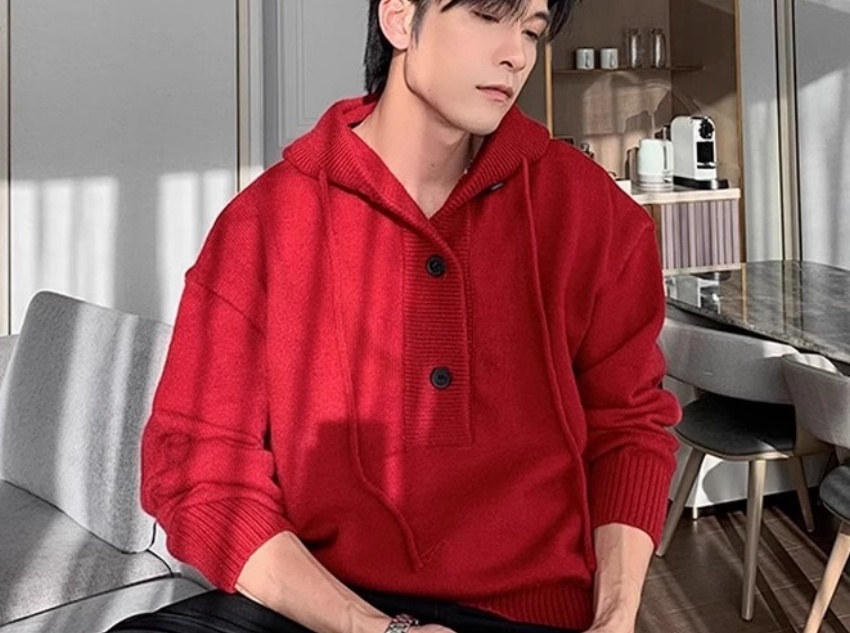

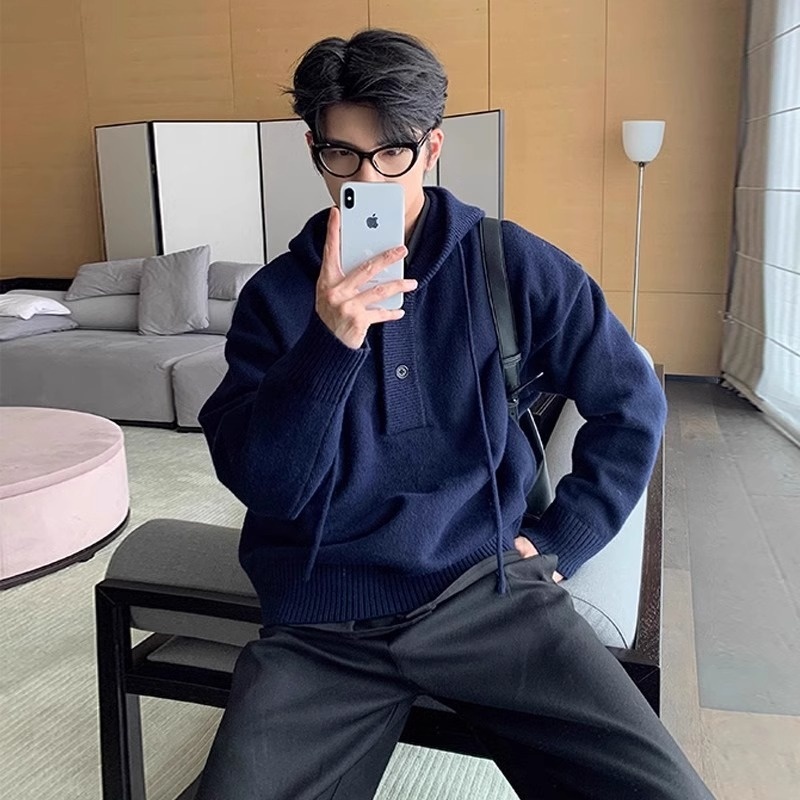

The picture shows a hooded men’s sweater. The hood of this men’s sweater is knitted in one piece. When the main body of the sweater is knitted, the hood body and the body are formed simultaneously. Through specific stitching (such as rib stitch transition connection), the hood body is naturally integrated into the body, ensuring the continuity of the overall structure and reducing splicing marks. If it is post-stitching, the hood piece needs to be accurately cut, and then the hood piece and the body part above the neckline are sewn with sewing techniques such as flat seams and overlock seams, so that the hat fits the neck and the brim has a natural curvature. It can effectively block the wind when worn, improving practicality and styling.

In the collar button area, the collar placket part is first knitted, and the placket thickness and stiffness are enhanced by increasing the knitting density (such as using tight stitches such as double ribbing) to provide a solid support for the buttons. Before installing the buttons, you need to punch or weave buttonholes at the corresponding position of the placket (such as using the keyhole needle method to make the buttonhole edge dense and not easy to unthread), accurately locate the buttonhole size and spacing, and ensure that the buttons (usually simple styles such as round or square, suitable for the sweater style) are installed. The opening and closing are smooth, and the collar shape is regular. After buckling, it can fit the neck, which is both beautiful and practical.

The cuffs and hems are both ribbed. When weaving, the ribbed needle method (such as 1×1 rib, 2×2 rib) is used. The elastic characteristics of the ribbed tissue are used to make the cuffs and hems fit the limbs tightly, not easy to deform and shift, and have good elasticity, which is convenient for wearing and taking off, and can effectively block the inflow of cold wind. In the knitting process, when knitting to the corresponding part of the body (the cuff is the knitting end of the sleeve piece, and the hem is the knitting end of the main body of the body), switch the ribbing stitch method, control the number and density of the ribbing knitting, and make the size and elasticity of the cuff and hem fit the overall sweater to ensure the comfort when wearing and the neatness of the shape.